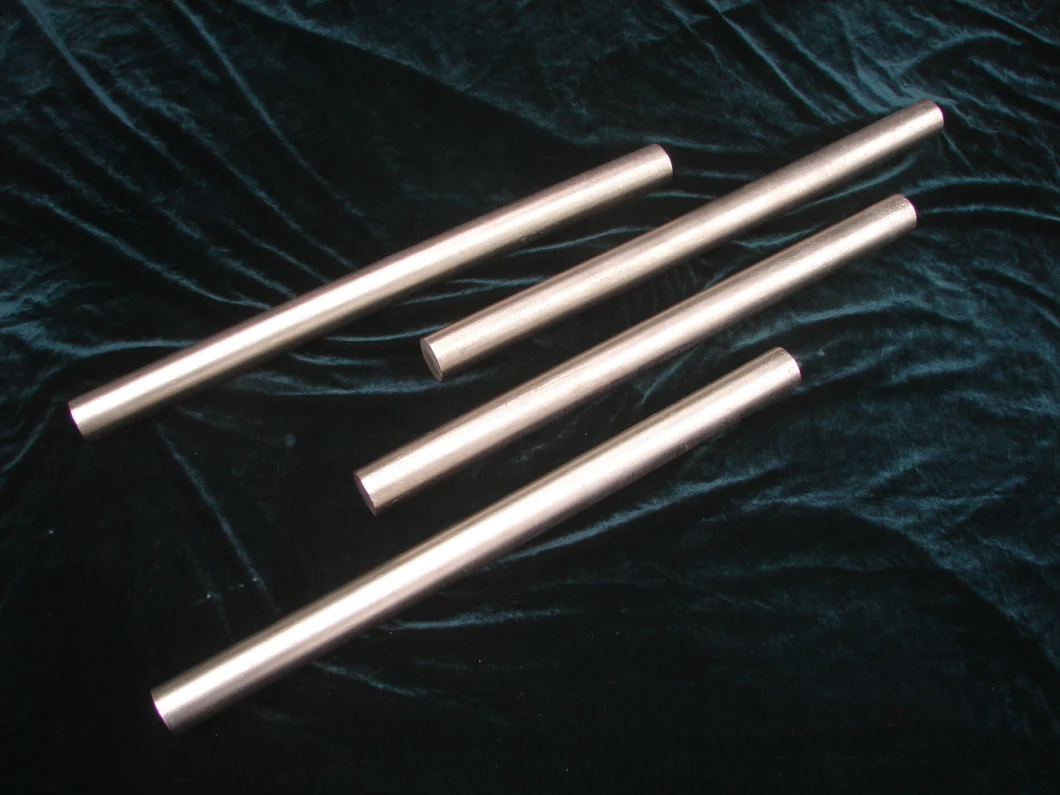

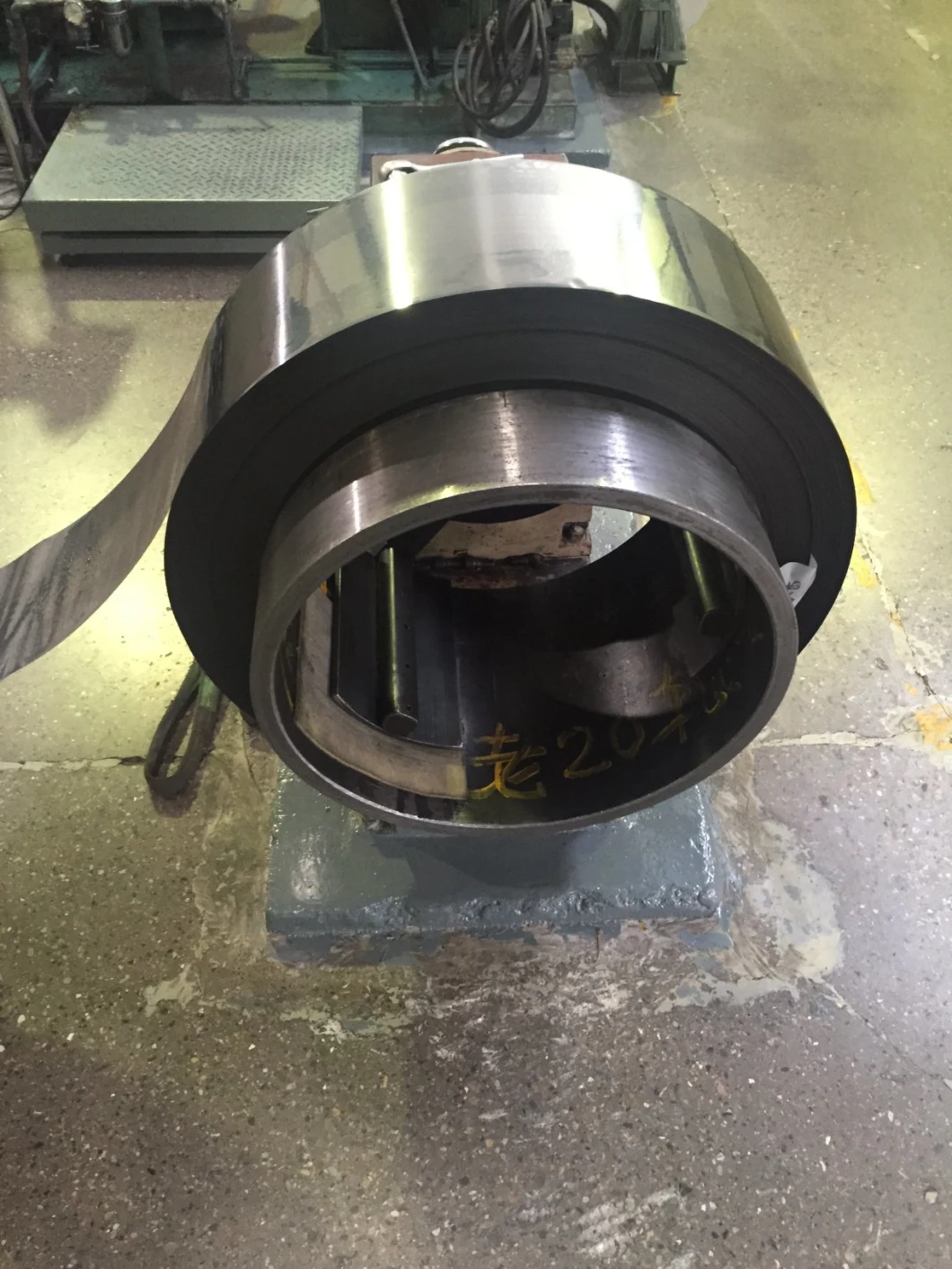

Nickel Alloys Rods/Bars Cast Alloys, Inconel 713c, In 713C, Alloy 713LC Used for Marine/Automobile Engine

Overview Product Description-A class of metallic materials that can work for a long time under the action of high temper;

Basic Info

| Model NO. | IN713C/713LC |

| Diamter | 45mm-100mm |

| Ratio | 100% Virgin or 60/40 Mix |

| Transport Package | Iron Boxes |

| Origin | China |

| HS Code | 75051200 |

| Production Capacity | 5000tons/Year |

Product Description

-A class of metallic materials that can work for a long time under the action of high temperature above 600ºC.-Features:- High temper-Oxidation and thermal corrosion resistance-Fatigue, fracture toughness, plasticity-Organizational characteristics:-Good stability and reliability -Industry Sectors:-Aeronautics and astronautics-Nuclear power industry-Petrochemical industry-Transportation industryDetailed Photos

| Element | C | Cr | Mo | Nb+Ta | Al | Ti | B | Zr | |||||

| Content | 0.08~ | 12.00~ | 3.80~ | 1.80~ | 5.50~ | 0.50~ | 0.005~ | 0.05~ | |||||

| (wt.%) | 0.2 | 14 | 5.2 | 2.8 | 6.5 | 1 | 0.015 | 0.15 | |||||

| Element | Fe | Si | Mn | Cu | Co | S | P | OET | Ni | ||||

| Content | ≤0.50 | ≤0.5 | ≤0.25 | ≤0.50 | ≤1.00 | ≤0.015 | ≤0.015 | ≤1.00 | Bal. | ||||

Chemical Component of 713LC

| Element | Cr | Mo | Nb+Ta | Al | Ti | Others | Ni |

| Content (wt.%) | 11~13 | 3.8~5.2 | 1.5~2.5 | 5.5~6.5 | 0.4~1.0 | 0.5 | Bal. |

| Condition | Tensile Property | Endurance Property | |||||

| TemperatureºC | RmN/mm2 | Rp0.2N/mm2 | A% | TemperatureºC | StressN/mm2 | Timehr | |

| cast | 760±3 | ≥760 | ≥620 | ≥3 | 982±2 | 152 | ≥23 |

You may also like

Send inquiry

Send now